YANTIAN East Port Development Project Proudly Recognised with the Designation of "Safe Construction Site"

A

A

A

缩小

加大

更大

Recently, the Department of Transport of Guangdong Province unveiled the list of provincial-level "Safe Construction Sites" exemplary projects for 2023 in road and waterway engineering, with only 10 projects making the cut.

Among these selections, YANTIAN East Port Development Project particularly distinguished itself as the exclusive representative from Shenzhen.

The East Port project is deemed a pivotal infrastructure initiative outlined in both the Outline of the 14th Five-Year Plan for Economic and Social Development and Longrange Objectives Through the Year 2035 of the People’s Republic of China and the Outline Development Plan for the Guangdong-Hong Kong-Macao Greater Bay Area, and YANTIAN places considerable emphasis on this project.

Since the inception of construction, the project team has placed utmost importance on establishing a "Safe Construction Site". This objective has been seamlessly integrated into the project's safety assurance system, daily safety procedures, and overall enhancement of safety practices. With a strong emphasis on "smart management" and "safety risk control," dedicated teams have been mobilised, comprehensive work plans have been developed, and a variety of measures, including monthly check, quarterly self-assessments, technological advancements, and meticulous supervision, have been put in place to ensure the effective implementation of safety initiatives. This concerted endeavor has resulted in the establishment of a robust safety management system.

△ Construction in the East Port

△ Construction in the East Port

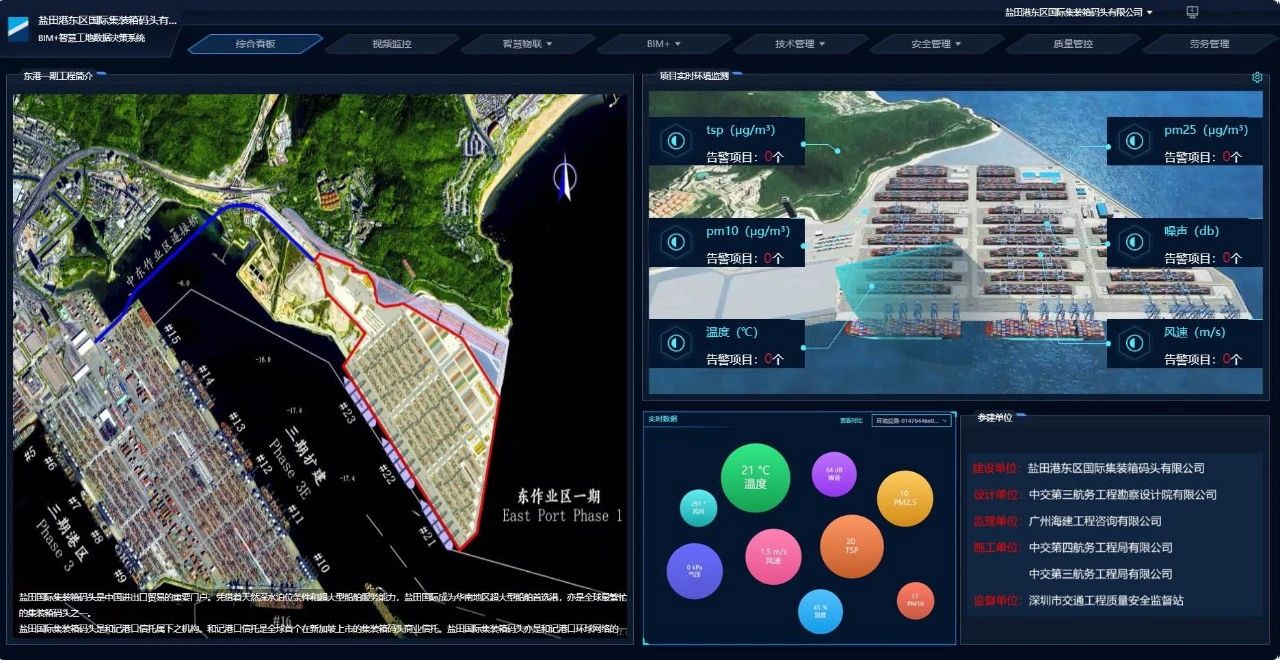

01 Harnessing the potential of new quality productivity and leading the charge in intelligent safety management.

✨Build an innovative offline smart exhibition hall

YANTIAN develops a comprehensive "smart construction site" management system capable of functionalities such as risk management, video surveillance (including patrol capture), power consumption monitoring, intelligent smoke detection, smart safety helmets, TSP environmental monitoring, and more, leveraging a robust management platform for on-site intelligent oversight.

✨BIM brings to life the visual simulation of construction processes (schemes):

1. Elevate overall perception analysis and control capabilities to grasp the critical and intricate aspects of safety management.

2. Assist in clarifying employees' safety management responsibilities and tasks, ensuring the efficient execution of safety measures.

3. Serve as intuitive safety training materials, facilitating comprehension among workers and yielding exceptional training outcomes.

4. Contribute to cultivating a safe and reliable working environment.

✨Robot-assisted pile inspection

This technology can optimise construction procedures. During the steel pipe pile production acceptance phase, conventional inspection methods are replaced by robots conducting thorough 360-degree inspections within the pile, effectively mitigating risks associated with personnel entering confined spaces for operational purposes.

✨Unmanned pile driving construction technology

It marks a paradigm shift in traditional methods of manually cleaning, operating, and checking piles. By integrating the RS-TV02 borehole television imaging instrument with mechanical equipment, operations proceed with heightened efficiency. Remote video monitoring facilitates meticulous control over the construction process within the pile, guaranteeing paramount safety for personnel through intrinsic safety measures.

✨QR code management

This measure improves the efficacy and accuracy of safety management spanning personnel, equipment, electricity usage, fire safety, hazard reporting, and so on.

02 Prioritising safety risk management to enhance production safety

In our commitment to construction safety, we place significant emphasis on comprehensive safety risk management. Before and during project execution, the construction organization has enlisted the expertise of a professional safety assessment organization to conduct a thorough risk assessment. This assessment meticulously examines various facets, including work areas, processes, hazard categories, severity levels, and potential accidents. Through intensified safety management efforts, reinforced allocation of safety resources, and the integration of cutting-edge safety technologies and preventive measures, safety risks are meticulously minimized, while any remaining risks are diligently kept within acceptable parameters. Furthermore, contingency plans have been formulated for potential risks, ensuring swift, methodical, and effective emergency response operations aimed at optimizing safety and mitigating losses.

✨Water-to-land construction technology

Enhancing traditional water-based construction methods for pile foundation treatment, this approach involves installing steel trestle bridges and work platforms to smoothly transform from water-based to land-based construction. By employing this method, the objective is to effectively mitigate safety hazards associated with coastal typhoons and the congestion of vessels in narrow waterways during simultaneous water-based construction, thus significantly reducing risks.

✨Safety management and control during water-based platform construction

A specialized platform management team has been established, consisting of members from construction, supervision, and project departments. Together, they meticulously oversee safety and quality aspects throughout platform construction, ensuring strict adherence to safety standards both during the construction phase and subsequent use.

03 Integrated operation of East Port, Phases I, II, III & Expansion projects, and West Port for optimal productivity

YANTIAN's cohesive management strategy across the East Port, Phases I, II, III & Expansion projects, and the West Port, has earned the distinction of six esteemed national-level engineering awards. Notably, these accolades include prestigious honors such as the Luban Prize, Tien-Yow Jeme Prize, and National Quality Engineering Award. These accolades underscore YANTIAN's steadfast dedication to upholding rigorous standards and achieving excellence in construction safety, engineering quality, and project execution.

1 Luban Prize, 2 Tien-Yow Jeme Prizes, and 3 National Quality Engineering Awards

The East Port is set to embark on the construction of three 200,000-ton automated container berths, spanning a total quay length of 1,470 metres. In the future, YANTIAN views the development of the East Port as a strategic imperative to drive forward the transformation of Phases I, II, III & Expansion projects and the West Port towards intelligence and sustainability. This proactive initiative is aimed at nurturing the holistic advancement of the East Port, Phases I, II, III & Expansion projects, and the West Port, fostering synchronised operations and shared resources.

The honor as one of the top ten "Safe Construction Sites" recognised by the Department of Transport of Guangdong Province not only underscores YANTIAN's steadfast dedication to safety in construction but also serves as a rallying call, motivating the project team to redouble their efforts. YANTIAN remains resolute in its mission to establish itself as a premium hub port, supporting Shenzhen's aspirations to expedite the development of a globally influential logistics centre. Additionally, we will actively cultivate collaboration between Shenzhen and Hong Kong for a mutually beneficial ecosystem encompassing port and shipping, modern logistics, and industrial supply chain services. This collaborative endeavor is poised to bolster the international competitiveness of the Greater Bay Area and contribute to the high-quality development of China's international trade.